From A to Green: A future vision of sustainable coachworks

Relevant Keywords:

Automotive industry, sustainability, Transportation, Delivery, Coachworks, Future scenario

Design Goal:

Combigroep Carrosserieën, a Dutch coachworks producer, wants to extend its potential market following the newest regulations, transportation trends and logistics of the European Union having sustainability as a focus. As a group of 6 interdisciplinary designers the project was carried out from the strategy up to the product interaction and product detail level.

Project duration and team:

300 hours, 2 Strategic product designers (Stefanus Heru Prabowo, Ricardo Mejia), 3 Integral product designers (Barth Vrijling, Ana Laura Rodrigues Santos, Marjolein van Houten), 1 Interaction designer (David Güiza Caicedo).

Methods Used:

- Vision in Product Design (ViP) was used as a design framework throughout the whole project

- The context of the industry and our clients position within it was researched and analyzed through stakeholder analysis, competitor analysis and PESTE analysis

- Interviews and role playing user analysis were used to understand our users and personas were used to illustrate them during the design process.

- Generated future scenarios

- Creative sessions were performed to generate ideas during the design process.

THE PROJECT:

The team intended to make a creative exercise by projecting a future vision that will finally inspire a realistic and influential product:A sustainable and versatile coachwork.

It is important to note that the project aimed at a sustainable approach in the broader sense of the word, so not only concerning ourselves with the environmental aspects of the product and the system, but with it’s social and economical impact.

A pioneering approach was developed through the analysis of future trends, drivers and forces – far until 2025 – so that this could be reflected in the opportunities of a design that can “launch” thePresent (2010) into this direction, while still following constrains and regulations imposed by a compliant industry.

Through the use of the Vision in Product Design (ViP) framework, a future scenario was built for the context and the transportation industry based on our thorough research and analysis and a future vision was conceived which would match the goals of the project and the industry.

Description of the final design

The Micro Delivery system (MDS)

The Micro Delivery System (MDS) is a new kind of business for Combigroep Carrosserieë in order to extend its potential market following the regulations and trends about transportation and logistics in the European Union. It is a new perspective for Combigroep Carrosserieë to work with (and in) different business like night delivery services, e-shopping or integrated deliveries.

The basic idea is to divide the big container on top of the truck into Micro Delivery Modules to increase the efficiency and effectiveness of the distribution of goods in cities, decreasing the amount of kilometres per route. The Micro Delivery Modules can be detachable to be loaded in the Delivery Centers (business) and to be unloaded and (or) used in the different contexts (users, which could be business or consumer). The modules also become a new channel for the collection of recyclable material.

Components of the system (for the case study – e-grocery):

g-combi – The g-combi is a platform with g-modules, the platform has a system with winches, locking mechanism and rails.

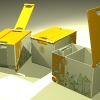

g-module – The g-modules are containers with empty space to organize different kind of goods. For the case study this container has a system of panels that provide room for the g-boxes with a locker system, a card reader (to activate the lock system) and a podium with wheels. The g-module works as a dispenser of g-boxes in the P+R (Park and Ride).

g-box – The g-box is a plastic box to carry groceries (35cm x 35cm x 50cm) to deliver goods in P+R. It was designed specifically for the e-groceries case study and as such it has a compartment for fresh products and one for refrigerated ones.

My role in the process

Although the nature of the methodology used and the composition of the design team allowed for a very decentralized and collaborative process to be performed, in which the whole team shared their opinions, insights and had input (to varying degrees) in all tasks, here is a list of some of my input throughout the process:

- Co-organized the application of the ViP methodology

- Actively took part of the research process and the various analysis performed

- Took part of the decision-making throughout the whole design process always advocating for the interests of the end users (the shoppers and the operators)

- Worked on the technical development of the ‘combi minimal’ concept

- Actively helped in the conceptualization of the g-module

- Designed the g-box

- Storyboarded and managed the development of the final animation explaining the e-grocery case study

SUPPORTING MATERIAL:

Documents (PDF)

- From A to Green – Executive summary of the project (PDF)

- From A to Green – Concept Discovery (PDF)

- From A to Green – Concept Design (PDF)

- From A to Green – Concept Development (PDF)